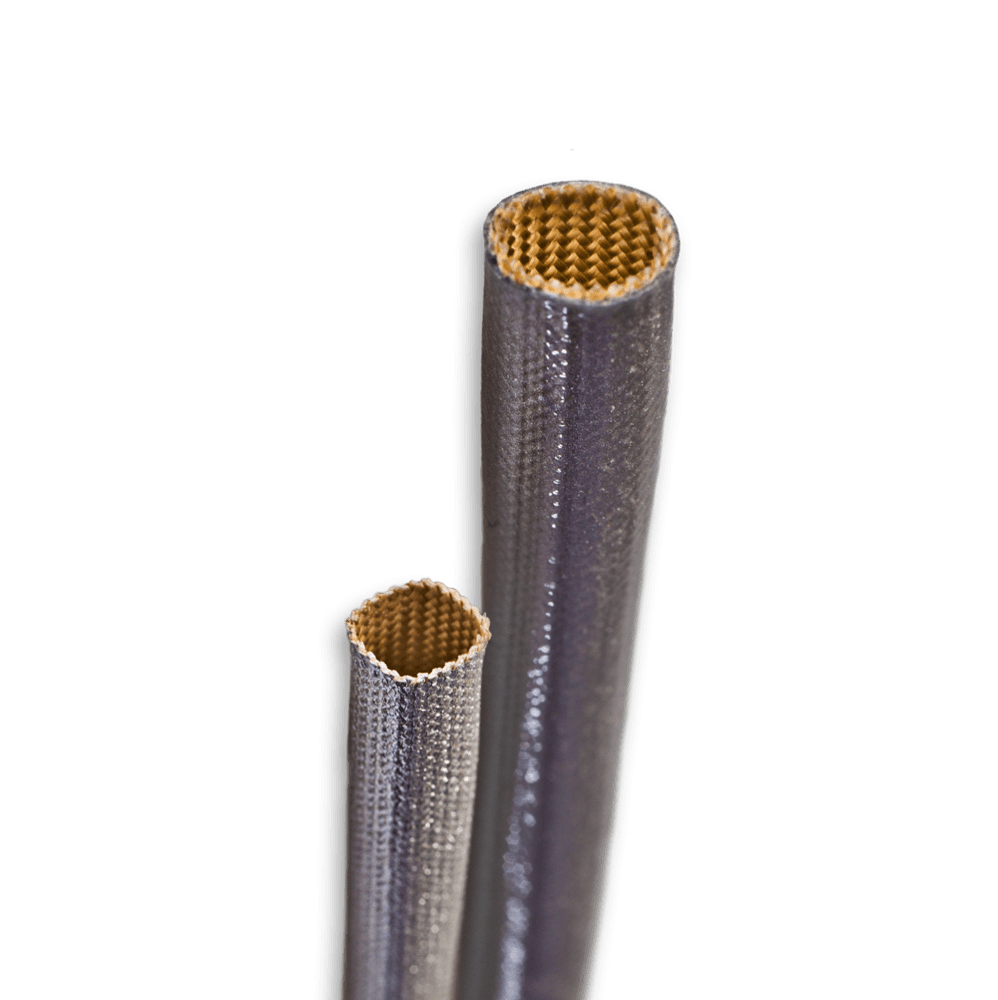

Bentley-Harris® Textalu 1202 is an insulative fiberglass sleeving with a heavy aluminum coating designed to protect components in high temperature areas. It provides superior insulation to components that must maintain stable temperatures to assure performance efficiency.

Textalu 1202 is used on wire harnesses, sensor control wiring and cable assemblies in close proximity to engines and exhaust systems. Due to its elastic structure, Textalu 1202 conforms well to the variable profiles of the components it protects. Its braided construction allows good flexibility in temperatures as low as -50°C.

The infra-red emissivity rating of Textalu 1202 heavy aluminum coating, combined with its fiberglass braid, ensures temperature stability inside the Textalu sleeving despite frequent external temperature fluctuations due to radiant heat.

| Nominal Internal Wall Thickness Standard Diameter (mm) | Wall Thickness (mm) | Standard Packaging (m) |

|---|---|---|

| 8 | 0.65 | 150 |

Features and Benefits:

- Slightly expandable tubular sleeve

- Excellent thermal protection

- Fiberglass construction withstands temperatures to 550°C

- Non flammable

- Conforms well to various profiles

- High flexibility

- Fray Resistant

- No skin irritation

Typical Applications:

- Wire Harnesses

- Electrical Cables

- Sensor Wirings

- Control Cables

- Tubings

| Test | Tested Property | Result |

|---|---|---|

| Temperature Rating | 200°C 550°C (Fiber Glass Braid) | |

| ISO 6722 | Heat ageing : 240h at 225°C | Neither any visible degradation or loss of flexibility Shrinkage < 10% |

| FMVSS 302 Test Method D45 1333 | Flame Resistance | Non flammable Type A |

| BH100-16 | Cold Bend Test | -50°C |

| Test Method D47 1098 | Fluid Resistance | No visible degradation or alteration after being immersed in: Diesel: 24h at 70°C Motor oil 15W-40: 1h at 80°C Expansion of coating after being immersed in Petrol, 98 octane, unleaded: 24h at 70°C Brake fluid DOT 3: 1h at 85°C |

Availability:

Bentley-Harris® Textalu 1202 is available in a range of sizes from 5 mm to 24 mm (ID).