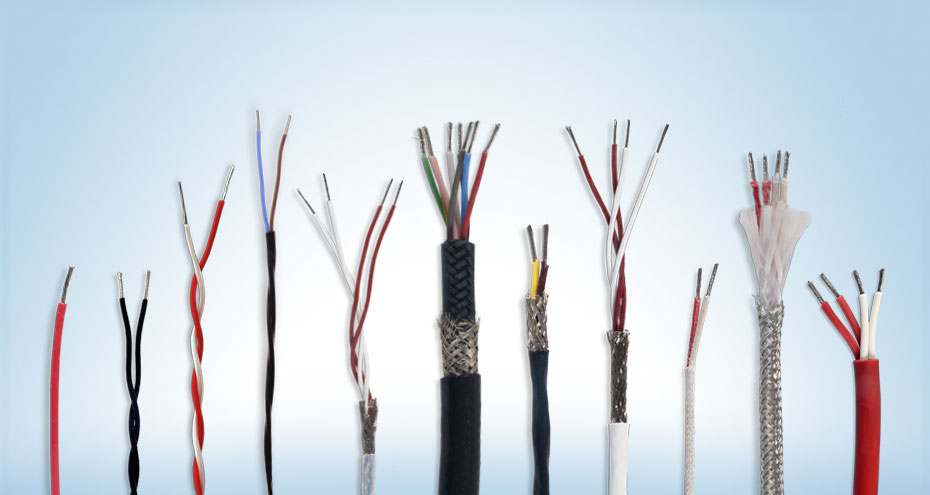

Connecting wires

Connecting wires are needed to connect resistance thermometers to a measuring device. Unlike thermowires and compensating wires, wires made from zinc-plated, nickel-plated or silver-plated copper or nickel wire are used. Nickel wires are only used for very high temperatures and are only available with fibreglass insulation. To make resistance thermometers as fine as possible, preference is given to using connecting wires with a small diameter (≤ AWG 24). This does however lead to an increased wire resistance which can be compensated for with a three or four-wire circuit.

1. Insulation materials

Fibreglass is spun or woven as a fabric around the wires. For applications under mechanical strain, further wrapping of the fibreglass-insulated wire with a VA mesh is recommended. Fibreglass-insulated wires are heat-resistant up to +1,100 °C, and with mineral insulation they can even withstand temperatures of up to +1,400 °C.

Teflon is chemically resistant to acids, bases, alcohols, petrols and oils. It is flexible and slides very easily, thanks to its low friction coefficient. It is also difficult to adhere to anything, since there are scarcely any materials that stick to Teflon. The usage temperature ranges, depending on the type of Teflon used, from -190 °C to +260 °C. For wire insulation, we use FEP Teflon (-100 °C to +205 °C), PTFE Teflon (-190 °C to +260 °C) or PFA Teflon (-190 °C to +260 °C).

Silicone is highly flexible and does not become brittle, even at low temperatures. Its usage temperature is from -50 °C to +180 °C.

A copper mesh is woven around the strands of some wires in order to shield the wires from electromagnetic interference. For particularly intensive stresses, such as of a mechanical nature or high temperatures, we offer additional protective tubes that provide the wires with especially effective protection.

1.1 Properties of insulation materials

| Material | Usage temperature

constant (°C) Approx. 25,000 h |

Usage temperature

temporary (°C) (hours) |

Dielectric strength

kV/mm (20 °C) |

General

chemical resistance |

|---|---|---|---|---|

| FEP | –100 to +205 | +230 | 25 | Very good |

| PTFE | –190 to +260 | +300 | 20 | Very good |

| PFA | –190 to +260 | +280 | 25 | Very good |

| Silicone | –50 to +180 | +250 | 30 | Limited |